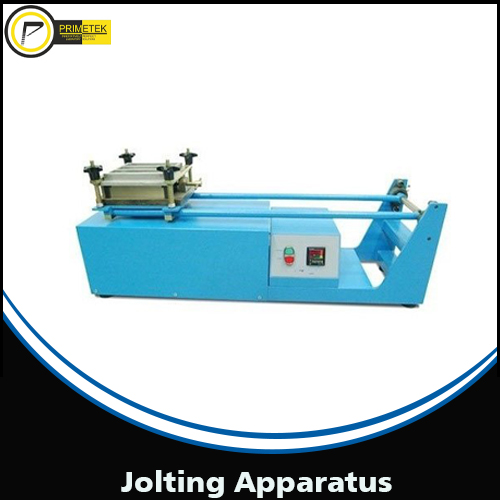

Jolting Appratus

GENERAL INFORMATION

Jolting Apparatus Used to compact cement mortar prisms 40x40x160 mm in the three gang mould containing cement specimens. The apparatus consists of a table holding the mould, seated on a rotating cam driven at 60 r.p.m. The drop height is 15 mm.

The apparatus consists of a table holding the mould, seated on a rotating cam driven at 60 r.p.m. The drop height is 15 mm. The machine is equipped with a digital counter which provides automatic shut off at end of preset drop numbers. Rapid mould lock and release system allows easy and quick operation. The supporting frame of the machine has been designed to ensure precise dimensions, table flatness, correct centering of the three gang mould on the table. The motor and gearbox assembly is enclosed in a protective housing, which promotes user safety (the moving parts are inaccessible) and long life for the gearbox.

Highly rigid structure, joints between main parts (table – arms – base) easily removable to check weights Drop height: 15 mm. Since the mechanical parts are subject to wear and tear and this height tends to change with use, the hammer has an adjustable height, making it possible to restore the initial drop height Motor: power: 250 W, 60 r.p.m., Overall dimensions (lxdxh): 310x1000x385 mm, Weight approx.: 55 kg

- The jolting apparatus consists of rectangular table rigidly connected by two support arms to a spindle at a horizontal distance of 800 mm from the centre of the table.

- There is a projecting lug with a plane face on the lower face of the table beneath which is a stop with a rounded upper surface.

- The table can be raised and allowed to fall freely by a cam which is connected to a motor. The cam rotates at a rate of 60 rev/min.

- A stroke counter fitted with micro‑switch is provided which stops the machine after 60 jolts.

- Locating pins are provided for mounting the moulds compartments on the table.

- The mould surrounded by the hopper can be clamped rigidly to the table.